Introduction

The effects of the COVID-19 pandemic are making themselves felt across the global supply chain. Although there have been other outbreaks and natural disasters in the past, COVID-19 represents a new type of threat.

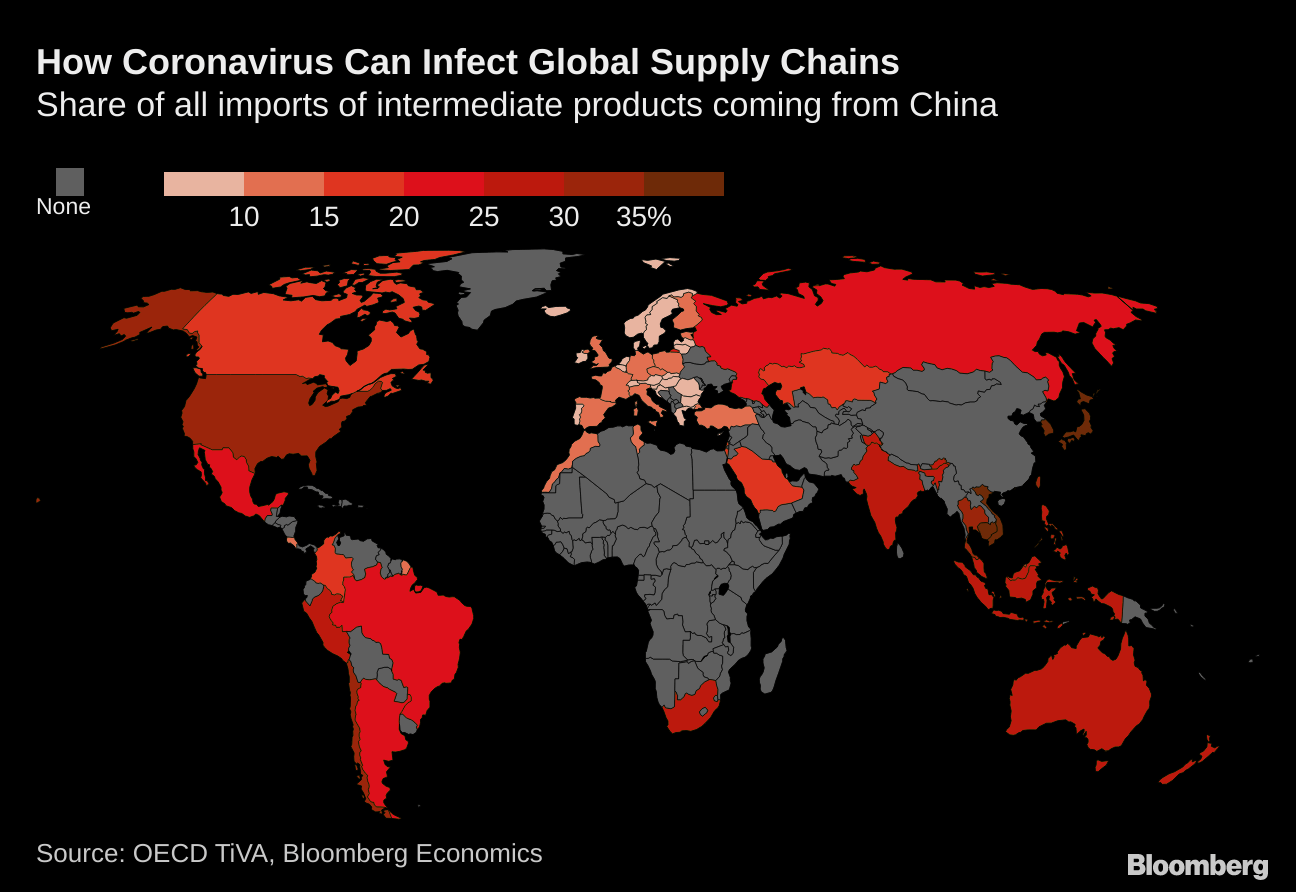

Today’s global supply chain is highly integrated and developed. This means that an impact on any part of the supply chain can have global implications. Not only has COVID-19 had a profound regional impact in China, but it may come to have a broader, and potentially more significant, effect on the global supply chain.

As the pandemic spreads to other countries, travel restrictions, shortages in labor and materials, and logistics delays may occur as factories, borders, and hubs are shut down—and because the supply chain is so deeply integrated, these effects can cascade and amplify. Many business leaders are struggling to respond to this new challenge.

How Coronavirus Can Infect Global Supply Chains

There may be three main impacts of COVID-19 on your supply chain:

- Production slowdowns due to a shortage of raw material and components;

- Increased legal costs as suppliers invoking force majeure contract provisions to avoid SLA penalties or breach claims; or

- Logistical delays resulting from travel restrictions, border closures, or shutdowns of transport hubs.

Many companies have responded to the pandemic by temporarily stabilizing their supply chains. This may prove to be short-sighted. The COVID-19 outbreak should serve as a wake-up call:

You need to make strategic, long term changes to increase the resilience of your supply chain, and you need to do it now.

Short-Term Strategy—Understand Exposure and Stabilize Supply

Your first step is to get informed. Appoint a direct report to lead your company’s response and efforts.

This person has two primary tasks:

- Get as much visibility into your supply chain and risk exposure as possible; and

- Take measures to stabilize your supply and production.

To gain insight into your supply chain and risk exposure, begin by asking these questions:

What are your critical components? What are the risks facing the Tier 1 – 3 suppliers of these components? Are there any “unique” components with only one supplier?

Where are your suppliers located? What’s the status of the pandemic in those regions?

Do your suppliers need support and if so, is there any way you can support them? How long do you expect them to be affected?

What are your current inventory levels, and where are they located? Can you move them nearer to your production facilities?

What components can be sourced from another supplier? How can you expedite the qualifications of a new supplier? Can you near-source or in-source these components?

Develop a plan to monitor and respond to supply disruptions and ensure that your inventory is accessible. Consider rationing critical components, pre-booking rail/or air freight capacity in the event that shipping is disrupted, using after-sales stock, getting a high priority from your suppliers, and supporting them during the crisis. Be prepared for unexpected spikes in demand (bullwhip effect).

Run scenarios for different timelines to identify risks, opportunities, and critical points of failure. Optimize your production by moving to your highest margin and/or highest opportunity cost products and move components to be as close to your production facilities as possible.

You can mitigate logistics risk by securing air or rail transportation as an alternative to ocean-based shipping. If necessary (and supported by your supply/production chain), obtain pre-qualified components or material directly from Tier 2 and Tier 3 suppliers when your Tier 1 supplier is affected.

Long-Term Strategy—Build Resilience

Your long-term strategy is about building resilience in your supply chain, so you aren’t caught off-guard during a crisis.

Building resilience lets your company weather the storm so you can focus on leading rather than crisis management, and companies who are resilient will emerge from crises stronger, more competitive, and better positioned to grow their business.

There are five components to building resilience in your supply chain:

- Assess your supply chain risks and create a risk management plan

- Gather critical data on your supply chain and set up 24/7 monitoring

- Build and strengthen relationships with suppliers, stakeholders, and partners

- Diversify your supply base by region and component, and establish alternate suppliers

- Map your entire supply network

By investing time and resources into these components, your company will be able to detect the early signs of disruption and respond quickly and confidently to secure your supply chain.

Global events like COVID-19 are the new normal, and the need to identify and manage global risks is the new normal for your business. Enhance your existing risk management strategy to include geopolitical, environmental, and global health risks, and consider expanding your landed-cost tools to include a factor for these risks. Invest in tools that can model alternate supply and logistics scenarios.

At the same time, invest time in understanding how to plan for disruptions by running simulations or scenarios. By using a simulation to plan your response to disruptions, define decision owners, and set roles and responsibilities you’ll be able to identify and correct weaknesses in your capabilities, so you’ll be prepared when a disruption occurs.

It’s vital to get as much information about your supply chain as possible and monitor that information 24/7. New AI and machine-learning technologies have made it easier and affordable to gather information on and monitor supplier networks. Just like you wouldn’t travel without insurance, you can’t run a global supply chain without being informed.

Make sure your visibility extends to your second and third-tier suppliers. The further you go into your supply chains, the more you know about where your components are coming from, and the more you can plan for and manage disruption.

Build strong relationships—it’s simply good business sense. It helps you get ahead of disruptions, and it helps you manage those disruptions when they happen.

Invest with time and resources, get to know your suppliers and their challenges, and engage partners who can help you build and manage your network, and it will pay dividends in increased supply chain resilience and stability.

Don’t put all your eggs in one basket. You need to have a supplier diversity strategy, especially if your business relies on global suppliers for critical components.

Your strategy should include geographic and supplier diversity to minimize risk exposure, and a plan to engage alternate suppliers in case of a disruption. That way, if a supplier or a region becomes unavailable, you’ll have a fallback.

While it’s great to know your suppliers, it’s even better to know who your suppliers’ suppliers are, where they’re located, and how they ship.

By building a detailed map of your supply chain, you’ll know the risks and challenges your suppliers face, where components originate from, and where they go.

When a disruption happens, you’ll know within hours which suppliers and components are affected, and what the effects are likely to be. This gives you valuable lead time to implement your diversity and risk management plans.

ISM conducted research on the effects of COVID-19 on the supply chain in late February. They conducted a second round of research between March 17 – 30th, with more than 550 respondents from their member and professional community.

Below are some of the highlights of the most recent survey, in comparison to the earlier survey. (ISM COVID-19 Press Release, 04/14/2020)

Of respondents reported longer lead times in China (up 8% over February).

NEW: 74% see longer lead times in Europe and between 34-44% from North American countries.

Up from 8% of respondents report an impact to operations in the first half of the year.

NEW: April is expected to be especially challenging with 39% reporting a severe impact.

Reduction in target revenue, down an additional 16% over February.

NEW: Only 1/6th of respondent pool reported decreasing revenue targets in February, while in March almost half reported negative impact to revenue.

Reduction in demand for products.

NEW: Some industries increasing revenue targets include Food, Beverage & Tobacco Manufacturing (+8.8%), Wholesale Trade (+0.3%), and Management of Companies & Report Services (+17.5%). Significant demand is hitting Health Care & Social Assistance (+50%) even as they adjust their revenue target -30%.

ISM Infographic

The ISM created an infographic outlining elements of its research into the supply chain impact of the COVID-19 outbreak in China. Follow the link to their site and the infographic, as well as more supply chain/COVID-19 tools and research.

MPK International is in no way affiliated with ISM (Institute for Supply Management). Their tools and research are available to be shared freely with those who have an interest in supply chain management.